The Art Of Tourbillon

The holy grail of watchmaking or a superfluous artistic flourish in the modern timepiece?

Related articles

We caught up with TAG Heuer’s Product Director, Guy Bove, to discuss the contemporary tourbillon and how his brand changed the game with some wondrous in-house mechanics.

Let’s briefly explore the history of the tourbillon. Why is this mechanism in many ways viewed as the holy grail of watchmaking?

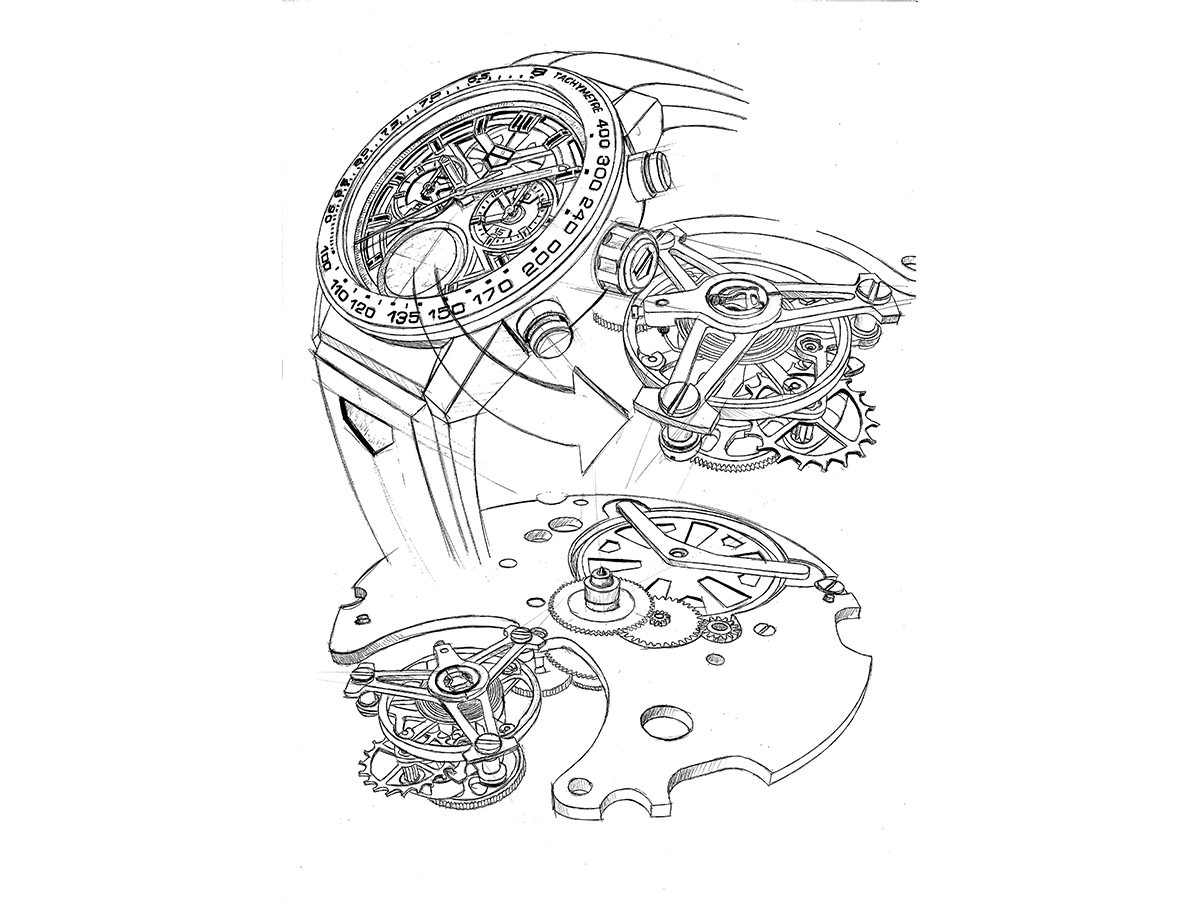

The tourbillon was patented in 1801, initially as a means of improving lubrification and regular wear of the escapement parts by continually moving them through all the points of a circle. In those days, the quality of the moving parts was comparatively mediocre and moving the spindles and parts through different positions was a way to avoid incremental errors by cancelling them out between themselves. Later on, the effects of cancelling out the gravitational effects on the escapement was discovered, and indeed a pocket watch with a tourbillon escapement held the world record for many years from 1892 on. These technical advantages aside, the need for a very light carriage and its permanent and rapid motion gave rise to a refined aesthetic, which has known many shapes and sizes and even rotational speeds since the invention of the tourbillon. This fertile playground for engineers, designers and craftsmen has undoubtedly given the tourbillon escapement the aura that we know today, as a visual signature and a fairly complicated form of escapement.

And your response to the occasional argument that a tourbillon is largely an element of art, unnecessary in delivering any great sense of modern functionality?

In a modern wristwatch that is worn regularly, neither the manufacturing quality nor the position of the watch has much effect on the precision of the escapement, hence this view. In a different view, one in which mechanical watchmaking plays a role of tradition, beauty, surprise, marvel, art is a function in itself, and a tourbillon in motion is a complicated, beautiful sight and an expression of the watchmaker’s art, which is often shown at the front of the watch. It brings the fascinating heart of the watch to the viewer’s eyes. Who would not be moved?

Is a tourbillon the most difficult movement to make by hand?

The tourbillon is not the most complicated ‘movement’ to make by hand – it is not actually a movement per se but a method of suspending the regulating organ, which is, in one form or another, the timing component of any mechanical wristwatch. However, as far as traditional escapements go, it’s clearly much more difficult to assemble and adjust than a fixed escapement.

Can you talk us through the carbon composite hairspring – what is this really, why is it so special, and what does it mean to a piece?

Modern escapements work, by and large, incredibly well. However, they have traditionally been made of metal alloys since their invention 200 years ago, which creates a number of issues for perfect timekeeping: comparatively heavy, they react to shock (dropping or banging for instance) by temporarily or permanently losing their spiral shape, which will automatically affect precision. Generally, part of the alloy is a ferrous metal, which means that it can be affected by magnetism, also impairing timekeeping performance and in extreme cases, stopping the movement (do not try this at home!). And as a metal, it can be affected by temperature swings. The idea behind Isograph is that by making a hairspring out of a non-metallic substance, making it extremely lightweight, making it non-metallic, we could effectively make an escapement that would be far less affected by these typical influences on regularity.

Fair to say TAG Heuer changed the game in 2006 with the unveiling of the Carrera Heuer-

02T tourbillon?

TAG Heuer clearly introduced a game-changer with that model and its follow-up models – a comparatively affordable, high-quality tourbillon chronograph that is Swiss made, with a very technical, cool look based on our legendary Carrera design codes.

How many parts live within the TAG Heuer 02T tourbillon?

We count 284 parts. This is a mechanism of such incredible intricacy and technical complexity – how has TAG been able to deliver it in such an affordable, accessible manner?

Firstly, the Heuer 02T is based around our Heuer 02 Chronograph movement, which has been painstakingly engineered for reliability and series production. Therefore, we are not in competition with ateliers specialising in products like one-off tourbillon movements – we see them as high-spec chronograph movements that are designed to be worn daily. Secondly, we are a global brand catering to many customers worldwide, which means that we are able to assemble even our tourbillon models in – comparatively speaking – sufficient quantities to bring the cost to our clients down without any effect on quality or aesthetics.

What do you say to those who think such an accessible price point means a lesser movement?

They are probably not the right customers for a race-inspired, hard-wearing, cool-looking daily wearer. We know that our tourbillon customers love the look of these watches, love that they can wear them everywhere and anywhere, and are able to afford the watch of their dreams. I would question what a “lesser movement” might mean – our movements are designed to high specification and reliability, and boast a great look which fits perfectly into the brand’s history.

This piece comes from our 2019 Summer Edition – to get your copy click here.

Subscribe to the Newsletter

Recommended for you

Top Gear

Segue from supercar to sand—and beyond—with Lamborghini and Orlebar Brown’s high-performance hook-up.

Follow Your Nose

Embark on an olfactory adventure with these location-inspired scents.

October 18, 2024

You may also like.

24/10/2024

You may also like.

Yachting’s Sea Change

Sure, the yachts dreamed up by big-name architects and designers look fabulous. But they are seaworthy?

Pleasure yachts were once the province of amateur sailors and oligarchs—men who, aside from a shared appreciation of varnished teak, adhered to diverging aesthetic templates. For serious mariners, form followed function, and fripperies were frowned upon. The upper-cruster aboard his gin palace, meanwhile, preferred nightclub chic, with heavy doses of gold, chandeliers and black-lacquered surfaces. Both types of vessel suffered from a surplus of wood panelling and a scarcity of sea views.

That design rulebook has now been thrown out, thanks to shifting priorities, new technologies and the pandemic-fuelled boom in yacht ownership. A rising generation of younger owners prefers watersports toys and wellness suites over cigar lounges and book-matched mahogany. Seductive superyacht concepts on social media promise a life in which families waft unbounded through fluid, open-plan, indoor-outdoor spaces devoid of clutter and supporting walls.

Suffice to say, such experimentation is not typically dictated by dyed-in-the-wool naval architects but comes from a fresh influx of creative outsiders from the land-bound worlds of hotels, private homes, furniture and even fashion. The designers serving the yacht-owning class of 2024 may be disparate, but they have one thing in common: boats are not their area of expertise.

For decades, a group of former apprentices of Australian Jon Bannenberg, the godfather of yacht design, dominated the field with their trademark lavish style. Bannenberg, part of London’s “swinging ’60s” creative wave, designed celebrated vessels for the great and the not-so-great, including Malcolm Forbes, Adnan Khashoggi and Robert Maxwell. Throughout the ’80s and ’90s, his protégés—Andrew Winch, Terence Disdale and Tim Heywood—catered to the tastes of their plutocrat clientele (think fussy mouldings, high-gloss hardwoods, tinkling crystal and veiny marble), with their brand names adding pedigree to ships and their style seen as the hallmark of opulence.

These designers “made a fortune”, says Giovanna Vitelli, chair of the Azimut-Benetti Group, by some distance the world’s biggest builder, who describes their style as “an institutional interpretation of luxury” dating from a more hierarchical era. “So, when I enter the yacht, I find a formal main salon, and then a big formal dining area, prepared to serve a lot of people,” she says. “I also stay away from the sea” due to privacy concerns, meaning small windows and high, enclosed sterns. This “shouted luxury”, in Vitelli’s words, is now giving way to a fresher, airier, more modern approach driven by a rejection of formalities and a new focus on “the very reason you go boating, which is the sea and nature”.

An embrace of the outdoors was a crucial focus for Norman Foster, one of the world’s most famous architects, whose designs for the 2008 YachtPlus fractional-ownership fleet, though controversial, prefigured some of today’s trends. Foster was perhaps the first outsider to disrupt the industry—“a conservative world” at the time, according to Angus Campbell, a senior partner at Foster’s practice who worked on the project: “You spend all this money, and then you have to look through these tiny little porthole windows; you’re on the sea, but you can’t see out. Why is that? So we looked at creating windows and external space that you can walk around.”

In 2010, Vitelli found herself asking similar questions and decided to hold design competitions specifically for creatives from outside the industry. A successful initial collaboration with architect Achille Salvagni that same year led to a series of partnerships with other architects known for their global portfolios of luxury retail, hotel, residential and product design, including Lazzarini Pickering in Rome, which did two interiors in the Benetti Motopanfilo line; Matteo Thun and Antonio Rodriguez in Milan, who are producing sustainable designs for the Azimut Seadeck series (the first of which will launch at Salone del Mobile this month); and Bonetti/Kozerski in New York, responsible for the interiors of Benetti’s 40M and 34M Oasis series.

Georgio Armani

The fashion icon’s design for the 72 m Admiral megayacht leans into his sophisticated, muted palette and prioritises outdoor space.

Roberto Palomba / Ludovica Serafini

The Milan-based architecture and design duo created the F100 Glass Cabin for Amer Yachts.

The results upended yachting convention. The traditional, strict divisions between interior and exterior were eroded, with “huge glass, huge doors” and a drop-down stern, recalls Vitelli, referring to Benetti’s pioneering “Oasis deck”—a lowered rear section with wings that fold down to create an expanded beach-club zone.

Other shipyards followed suit. One particularly radical concept was the 2015 Savannah, created for Feadship by Cristina Gherardi, who previously was director of architecture at Dior and designed projects for Armani Casa. The yacht featured multiple innovations, including hybrid propulsion, an engine ventilation that filtered air through tables in the bar, and a partially submerged glass-walled Nemo Lounge for watching passing fish.

Oceanco, a full-custom builder that counts Jeff Bezos and Steven Spielberg among its clients, now works with non-yachting designers under its NXT program, while Amer, a smaller semi-custom brand from the Permare Group, recently partnered with Milan-based architectural studio Palomba Serafini to create the award-winning F100 Glass Cabin. And in 2020, Giovanni Costantino, founder and CEO of the Italian Sea Group (TISG), reeled in the Moby Dick of designers: Giorgio Armani. The fashion maestro, who has owned his own yachts for two decades, not only signed up to create two Armani-branded 72 m Admiral megayachts, including one that launched at the Monaco Yacht Show this year, but also bought a 4.99 percent stake in TISG.

The brand-name appeal of famous designers targets a new type of buyer, one who shops for a yacht as they would a luxury car, says Philippe Briand, a naval architect and creator of racing vessels as well as Vitruvius superyachts. The previous generation “came with sailing experience”, he says, “so they were more aware of functionality and constraints. Today, this generation are newcomers, and they’re consumers. That’s fine, but they need to be a bit educated about how complex it is to create a boat.”

Ownership is expanding and changing. There were 1,203 superyacht projects under construction in 2023, according to the Global Order Book, an annual industry survey. That’s nearly twice as many as a decade prior, and demand looks likely to grow in line with the boom in multimillionaires: the most recent UBS Global Wealth Report predicts that the number of people with over US$50 million (around $76 million) in assets will rise to 372,000 by 2027, up from 243,060 in 2022.

“In the past, rich people were mainly over 50, and now it’s completely different,” says Antonio Rodriguez, co-designer of the Azimut Seadeck series. “There is a boom of younger rich people, especially in Asia.”

Gregory C. Marshall, a veteran naval architect based in Victoria, Canada, says his millennial clients (some of whom are in their 20s) “just don’t seem to be interested in traditional superyacht thinking”, adding that “they travel with a backpack and surfboards”. They want ships that are “less polished on the outside and a little more ‘How many toys can I pile on?’ ”

Enrico Bonetti/Dominic Kozerski

Bonetti/Kozerski, based in New York, aimed for nonchalant elegance with its Oasis series for Benetti.

Norman Foster

The Pritzker Prize–winning architect kicked off the “outsider” boom with his envelope-pushing YachtPlus.

But yachts are still status symbols: no one buys a superyacht solely due to a love of sailing. “If people like the sea, in general they buy a sailboat,” Rodriguez notes. For grander vessels, clients see no reason not to bring in a famous name with no knowledge of the category “like they use a designer for a house in the city or in the countryside,” he says. “It’s a floating house.”

Roberto Palomba’s vessel for Amer was commissioned by a client for whom he had designed projects on terra firma. “He knew me and he loves my style, so he wanted my style in his yacht,” says Palomba, who had no previous marine experience.

The older generation of owners believed that conventional layouts by established industry professionals locked in resale value; today’s clients are much more comfortable with risk. Concepts aimed at this market include vessels shaped like sharks, the Star Trek Enterprise, and bird skeletons. Oceanco’s NXT offerings include Aeolus, a 131 m gigayacht with a huge, sculpted primary suite and panoramic windows, and Kairos, which has the cosmic, asymmetric feel of a Tokyo shopping mall.

“It’s a less formal naval feeling onboard nowadays,” says Paris Baloumis, group marketing director at Oceanco. “Space has become much more fluid.” The aim, he says, is seamlessness between interior and exterior, work space and private space. “Back in the day, you had a special area for aperitifs, maybe a cigar lounge. A lot of different spaces dedicated to specific functions.” In contrast, Oceanco’s NXT Tank concept has replaced rooms with three amorphous zones.

Much of the work of external designers involves removing clutter. Giorgio Armani tells Robb Report that his blueprints were inspired by the clean lines of military vessels “and the optimization of space characteristic of old ships—away with all the infrastructures that can normally be seen, such as the tenders.”

Inside his Admiral yacht for TISG, windows feature sliding panels to help create “spacious interiors flooded with natural light”, he says. “The sensation is wide-ranging and of total immersion in the surrounding environment.” The effect, enhanced by the stealth-wealth decor, recalls his relaxed yet deceptively decadent suits.

Touring yachts as part of his research for the Oasis series, Enrico Bonetti, of Bonetti/Kozerski, found the interiors “very stiff, rigid, with furniture where nobody would sit” while also prioritising “something flashy here, something else flashy over there. So what we tried to do is to link all the spaces together and have a continuation of materials and textures and colours.” The aim, he says, is nonchalance: “sophisticated but without showing it too much”.

The main difference between the old and the new is a shift away from ostentation and toward a discreetly refined simplicity. Rodriguez’s mantra is “Always remove”. Instead of a bunch of gold and marble, he says, “we try to do the opposite, to keep only the materials you need, and never, never to show off.” He calls this approach the new luxury.

Technology is also altering the design process. Engineers at Azimut-Benetti no longer make test models, instead using Oculus virtual-reality glasses to “walk” around the boat, making adjustments in real time. “The ability to do large, technical, structural glass has evolved enormously,” says Marshall, whose studio produced the Artefact superyacht, which may lay claim to more glass than any other yacht on the water and won two major awards at the 2021 World Superyacht Awards. Technological advances engender new ideas, he says. “You start to think, ‘Well, if the glass is actually stronger than my aluminium structure, why would I make it out of aluminium and not glass?’ ”

Sustainability is another driver of change. For the interiors of Azimut’s Seadeck, Rodriguez says he selected exclusively recycled or recyclable materials, including a carpet made from discarded fishing nets, which Vitelli describes as “pleasant to touch”. She adds, “You don’t have that cold plastic effect—it’s like silk.”

“We were trying to push the boundaries and create a better experience for the guests, rather than make it easy to tie up when you’re trying to bring it into shore.”

Change isn’t always welcomed by the technical teams who have to turn outsiders’ nautical fantasies into seaworthy vessels. “I’ve seen a lot of examples of yachts which have been controlled by the interior designer, and in the end [it] does not hang together,” says Philippe Briand, the naval architect, who prefers to work only with marine-specific interior designers.

He particularly abhors the proliferation of unrealistic concepts on social media: “They’re all fake, to be honest, because they’re not representing any existing boat—they’re only the dream or the marketing of a young designer.” Moreover, these renderings are “polluting the market”, he says, because they give clients improbable expectations. “The client says, ‘You’re creative, you’re inventive, so I’m going to order a boat from you [only] if you’re able to do the same design I saw’. Which puts us in a very difficult situation.” Briand cites the trend for ultra-low beach clubs, which he calls unfeasible in even slightly choppy water. “To make an attractive image in a magazine,” he says, the rendering needs to be “flat, all open, two feet above the water—and, of course, on the rendering, the water is [also] flat. It’s not corresponding to any real functionality. I mean, it’s basically fashion.”

Antonio Rodriguez / Matteo Thun

The first in the Azimut Seadeck series by this Milanese partnership, which debuted in April at Salone del Mobile, features all recycled or recyclable materials.

Marshall, the Artefact’s architect, agrees that clients often bring concepts that are impractical but usually finds that, with “some minor adjustments”, the designs are “buildable without losing the aesthetic inspiration”. He says it largely depends on the purpose of the yacht, with an oceangoing vessel requiring more serious engineering than a Monaco posing platform—not every model needs to be able to “survive a hurricane in the middle of the Atlantic”.

Marshall likewise welcomes the creative tension inherent in a meeting between external creatives and in-house engineers. “We look at it like a war,” he says, cheerfully. “Because the reality is each discipline is in conflict with the other disciplines. You may love the styling, but the structural people go, ‘Thanks, how do I build that?’ The way he manages the mediation process is to “start with the concept, go to a certain point and stop, then do a structural pass, then do a mechanical pass, [then] go back to styling—and the stylists of course look at it and go, ‘Oh, my gosh, all these engineers just slaughtered my brilliant design. And we go round and round.” The conflict is the point, he says. “When you get the balance right, then it’s a good design.”

Baloumis agrees but admits to “frustrations on both sides”. Outsiders lack “the technical understanding of naval architecture”, at which point “we have to really guide [them] to understand why certain things are not possible. But on the other hand, it also pushes us to see how we can make it work. And that is a nice interaction.” This Darwinian-esque struggle is necessary, he says, “because the yachting industry is quite confined, quite closed”.

Palomba and Bonetti both encountered resistance to their initial ideas for Amer and Benetti, respectively. According to the former, he had to “force the producer to create big windows”, while Bonetti recalls continually clashing with what he refers to as “the rules”, such as having an elaborately set but unused dining table in the main salon. “For us, not knowing the rules [made it] easier to do things a little bit differently.”

That often-fruitful tension between outsiders and insiders can tip out of balance in the presence of what Marshall calls a forceful stylist. He’s happy to incorporate “round windows, triangular windows, giant staircases”, as long as the vessel operates as more than a stage set.

One veteran yacht designer, asking not to be named, points to Foster’s YachtPlus as an example of form outweighing function. “It just didn’t function as a boat that well, in terms of the normal day-to-day things, like simply tying it up. A lot of the aesthetic inspiration that non-boat people come up with is very clever, but if it doesn’t meet the core usage, it doesn’t last very well.” Campbell, of Foster + Partners, says that their brief was innovation and readily admits that they prioritised eye-catching radicalism over the nitty-gritty of nautical functionality. “We were trying to push the boundaries and create a better experience for the guests,” he says, “rather than make it easy to tie up when you’re trying to bring it into shore.” Those choices, he says, are often in direct contradiction, adding, “I think what happens with a lot of yachts is that the crew take a lot of the key spaces. And the fact is that the guests who’ve paid for the yacht get all the spaces that are left over. We did question a lot of those items to try and push it because, you know, how [else] do you get innovation?”

Maritime regulations often curtail the ambitions of owners and designers. A client’s desire for double-height ceilings is hard to square with fire regulations, which limit the number of open spaces. “A boat is not a bag, it’s not a dress,” says Vitelli. “There’s a lot of substance—you’re buying a floating object full of technology, so [safety] has to remain the priority.”

In terms of interiors, most still agree that the nautical nature of a yacht should be reflected in its fixtures and fittings. “A boat should remain a boat and should remain marine,” says Vitelli, adding that she rejected some architect proposals that were too close to “a New York loft”. Bonetti also cautions against mimicking residential styles too closely. “We’re seeing some boats that if you [replaced] the view from the windows with a street, it could be an apartment in the centre of Berlin,” he says, adding that vessels can reflect their authentic purpose “without going back to the old mahogany interiors”.

But exactly how should a yacht’s design convey its marine essence? It’s partly a matter of safety, says Vitelli: it must have “rounded shapes”, because no one wants to encounter a sharp corner in a storm; handrails and non-slip floors are also crucial. But for a superyacht, it’s also a matter of luxury aesthetics—which means bespoke built-in furniture. Anything off-the-peg “is not perceived as top luxury by certain customers, it’s luxury that we can more or less all afford to buy—Poltrona Frau or Minotti.” In other words: mass luxury.

Bonetti agrees. “The majority of the furniture and the millwork should be specifically designed for that boat,” he says. “It shouldn’t be something from a showroom.” Palomba, however, prefers “movable pieces from brands like B&B and Talenti”, specifically to get away from “integrated fixed furnishings,” which for him are too redolent of the moulded-fibreglass fixtures of yesteryear.

When is a boat not a boat? When it is, in Armani’s words, “a moving house, with particular characteristics”. Today’s owners employ residential architects precisely in order to create the feel of a floating home. Such personal designs will inevitably conflict with the mathematical certainties of naval engineering. But the best shipyards welcome outsiders who bring the friction that sparks creativity—such open-mindedness is especially necessary as technology continues to expand what’s possible. Yacht design is not “an ever-fixed mark / That looks on tempests and is never shaken,” as Shakespeare might have it, but instead it must trim its sails to the prevailing wind. ●

THE NEW DELIVERABLES

Thanks to the influence of big-name designers and the growing owner demand for increased space and superior views, superyachts are undergoing a style evolution. Three areas in particular are coming into sharper focus for builders

Active Beach Clubs

The leisure space at a yacht’s stern has become an essential part of the superyacht blueprint. Owners’ emphasis on the water’s edge has given rise to active beach clubs, which might feature enclosed lounges, drop-down transoms for watersports access, or multi-decked havens where relaxation meets wellness meets seaside living. Most beach clubs come into their own when the yacht is at anchor, but aboard Oceanco’s Aquijo, the world’s largest high-performance ketch, watertight doors mean guests can still use the jacuzzi, spa pool, hammam and sauna when sailing at top speeds.

Glass-bottomed jacuzzis and glass-encased pools on the main deck, as seen on Golden Yachts’ 88 m Project X, shine natural light on a beach club below, mitigating a lack of windows. Other solutions include side terraces that extend the footprint, a trick used by Bilgin’s 80 m Leona. The third hull of the Bilgin 263 series, meanwhile, takes enclosed beach clubs to a new dimension: marble runs across the walls and floor, while a ceiling decorated in twinkling LEDs illuminates a tiled pool and statues recalling Ancient Greece. On the starboard side sits a bar embellished with amethyst and agate; on the port side, a hookah room with fold-down sea terraces.

Rounded Interiors

Several design firms, including Burdifilek of Toronto, are employing curvaceous hull shapes to form new fluid interiors. “I believe very strongly that you should feel like you’re on a boat, with bulkheads that hug the curve of the hull,” says Burdifilek cofounder Diego Burdi, who went with a more rounded feel for the 61 m Damen Entourage.

It’s a sentiment echoed by Rome-based Lazzarini Pickering Architetti, whose interiors for Benetti’s Motopanfilo series are framed by curved, structural “ribs” and integrated panels that mimic the shapely nautical doors and smaller portholes of vessels from the ’60s. Others, such as the Maiora 35 Exuma and the WallyWhy150, feature domed ceilings that don’t compromise structural integrity. “You have to be brave enough to push the boundaries and shift existing design parameters,” says Luca Bassani, Wally’s founder and chief designer.

Virtual Pilothouses

A mere fantasy five years ago, the virtual pilothouse is close to reality now. Some builders are doing away with the main-deck bridge altogether, as seen with Sunseeker’s new Ocean 182, which has only a single helm on the flybridge, as well as Feadship’s concept, Pure. Instead of being perched at the front of the yacht, the captain and VR “command centre” are discreetly ensconced in a windowless deck below the waterline. Team Italia’s virtual bridge isn’t, as the name suggests, virtual but trades its traditional territory for a less prominent position of the owner’s choice.

Placing the pilothouses in out-of-the-way corners allows owners to appropriate the best forward views for their own main-deck suites. The days when practical, nautical concerns necessitated that captains occupy such prime real estate are in the past: “Considering the data and virtual reconstruction sensors we now have,” says Massimo Minnella, CEO and founder of Team Italia, “a virtual bridge will be just as safe and capable as the current one.” The Grecian-inflected pool of the Bilgin 80 m Leona’s beach club; the “command centre” aboard Feadship’s design concept Pure; Benetti’s Motopanfilo 37M’s main salon, featuring structural curved “ribs”. Photography: Daniele Venturelli/Getty Images (Giorgio Armani photo); Enrico Costantini; Ludovica and Roberto Palomba.

Photography: Nigel Young

You may also like.

18/10/2024

Entrepreneur Blake Johnson on Buying a Soccer Team, His 1969 Bronco and His Favourite Watch

The self-made businessman went from working on a ranch to launching businesses worth over $2 billion.

Johnson’s rise, from waking at 3.00 am to work cattle on his family’s California ranch to becoming a self-made billionaire, began at school—but not necessarily in the classroom. “I remember running round corners trying not to get caught selling lollipops,” he says. At 47, Johnson has created and sold businesses for a combined total of around $2.3 billion. His direct-to-consumer orthodontics provider, Byte, reached a billion US dollars ($1.5 billion) in valuation without any external investment; Alter, a fitness brand focusing on DNA and daily biometrics, “is on a trajectory to exceed that number by multiples”, he says. His seventh enterprise—a consumer-finance company, Forma—has just launched.

Success has allowed Johnson to explore passions including art, watches, pens and philanthropy. “I’ve had so many lucky breaks along the way—especially at the age when the concrete is still wet, so to speak—and I’ve always felt compelled to give back,” he says. Beneficiaries include International Justice Mission, Heart of Los Angeles (HOLA), and various arts, science and educational establishments.

Johnson is perpetually on the move but finds himself returning to a long-term aim: “I’ve become obsessed with starting a school for kids from 12 to 20 years old. I believe I can fix core problems existing in our education system.”

What have you done recently for the first time?

Became an owner of a sports team. I invested in a UK soccer club called Hampton & Richmond Borough FC. I went out there to go to a game in January, but the pitch was frozen.

First thing you do in the morning?

I like to knock out the items I’m least looking forward to: from workouts to analysing financials to difficult decisions and hard conversations.

Do you have any personal rituals?

I love to travel by myself. I appreciate travelling with my family and friends, but being on the road solo is liberating. I’m perpetually curious and yearn to see what’s over that next hill and meet the next person.

What do you do that’s still analog?

I have a collection of fountain pens, each filled with a specific brown ink, and I keep cream-coloured stationery and cards to write letters on. I write in cursive script and take great care with each presentation. It’s becoming a lost art, but one that I’ll never let go of.

Jeff Lipsky

What in your wardrobe do you wear most often?

I’m not shy to rock a scarf any chance I can. I’m a sucker for Loro Piana. I’m headed to Africa tonight, and the family member I’m travelling with joked that I needed to pack an extra suitcase for all my scarves.

Drive or be driven?

Nothing makes me happier than being behind the wheel, but I’m now driven the majority of the time. I own a few cars, including a 1969 Icon Bronco. It’s a real head-turner. You’re driving along and people are honking and giving you thumbs-up. The car I’m driven in mostly is a [Cadillac] Escalade.

Jeff Lipsky

What’s your favourite cocktail, and how do you make it?

Year-round in Southern California: tequila with a splash of soda water and a slice of orange. Summers in Lake Como: negronis. Winters in England: elevenses with the boys. Mexico: cerveza with tobala mezcal neat.

Who is your dealer, and what do they source for you?

CJ, hailing from London and Monaco, is well on his way to becoming the biggest contemporary-art dealer on the planet, and I find myself heavily following his lead on blue-chip artists.

What’s the most recent thing you’ve added to your collection?

A piece by George Condo, Mr. & Mrs. Strange. You see some great artists—from Richard Prince to Damien Hirst—shift their style. This one blended an old style with a new style on the same canvas.

What’s the most recent thing you regret not buying?

More real estate in 2021, when it was better to be lucky than to be good. I had my eye on a ranch in Colorado that I passed on, and I still mourn it weekly. It’s funny, they say you spend your early adult life running away from your childhood and your later adult life running back to it.

How do you get to sleep?

I fall asleep within 30 seconds of my head hitting the pillow. I’m an early-to-bed, super-early-to-rise guy. It comes from having to get up at 3.05 am daily to work cattle in my youth.

What does success look like to you?

My views of success constantly change. Having my children balanced with broad perspectives and fundamentally strong characters is top of the list.

Who is your guru?

I’ve always prided myself on not having one and carving my own way through life. However, I’ve recently had the good fortune to spend days with Guy Ritchie at Ashcombe, his estate in England. Brief moments of conversation with him have forever changed my views on life and humanity. His EQ [emotional quotient, more commonly known as emotional intelligence] is off the charts.

Are you wearing a watch?

Yes, a Patek Nautilus 5976—my favourite piece out of around 25 I own.

Jeff Lipsky

How would you describe your look?

Multifaceted. I love British sophistication, Italian understated elegance, American Western wear. But most importantly, I love a good tailor. Regardless of style, if it’s not fitted, it’s not right.

What’s your favourite hotel?

It’s a tie between the Mandarin Oriental in Lake Como, the Brando in French Polynesia and Claridge’s in London.

Who do you admire most in the world?

I admire those who live [in] the arena, whose faces are weathered by hard work, valiant efforts and material results. I admire anyone with grit, the nimbleness to think on their feet and a strong positive attitude.

Last piece of advice you gave?

There are three essentials in life: something to do, something to love and something to hope for. If you’re missing one, life will be out of balance.

And the last advice you were given?

Grasp the difference between jungle and zoo lions. Independence is earned, dependence is free. No one ever did anything impressive in the zoo.

What kind of music makes you happy?

From George Strait and Chris Stapleton to Maná or Luis Miguel to George Michael and ’80s pop to Motown and [Norwegian DJ] Kygo and other EDM.

You may also like.

24/10/2024

18/10/2024

Top Gear

Segue from supercar to sand—and beyond—with Lamborghini and Orlebar Brown’s high-performance hook-up.

Fasten your seatbelts, Automobili Lamborghini and Orlebar Brown are racing to the shore with a new swim, beach and resort collection. The dashing new capsule range comprises swim shorts, polos, resort shirts and trousers, polos, and t-shirts to take you from supercar to sand, then onto the bar or restaurant.

Each piece is a nod to the exotic colours and inspired details that the marque’s owners and fans will appreciate, including the legendary hex of Lambo exhausts and vents. Even better, the collaboration will run for three years. Which sounds like an awesome fashion road trip to us.

See more at orlebarbrown.com; lamborghinistore.com

You may also like.

24/10/2024

18/10/2024

Follow Your Nose

Embark on an olfactory adventure with these location-inspired scents.

At the end of a memorable visit to the Dominican Republic, Robert Gerstner decided to commission a souvenir. He’d been fascinated by the aromas of cigars being rolled and boxed during a factory tour, so he asked his friend and travelling companion, the perfumer Bertrand Duchaufour, if he could bottle the scent.

“I didn’t really think there were any great tobacco fragrances out there,” Gerstner says, and he would know. For nearly 30 years he’s run Aedes, a New York City perfume shop that offers exclusive scents, including an in-house collection called Aedes de Venustas. The newest, Café Tabac, debuted last December and is the product of Duchaufour’s efforts. It’s named for the Big Apple’s long-shuttered supermodel hangout, but the scent is redolent of the Dominican Republic’s key export.

Since then, a raft of houses have launched scents that are either directly evocative of, or otherwise inspired by, specific destinations—a trend that makes sense given our near-insatiable thirst for visiting new places. “Locations are one of the main things fragrances stir up in you,” Gerstner says.

“It just happens that you get inspired by travelling.”

Arquiste A Grove by the Sea

Lopud, Croatia

This small island in the Adriatic Sea has forests of pine, cypress and some of the tallest palms in Europe. The scent, created with perfumer Rodrigo Flores-Roux, captures the sea air that blows through their leaves and fronds to combine with the crisp aroma of locally grown thyme, rosemary and figs. Around $330 for 100 ml

Louis Vuitton Lovers

Virginia, USA

Pharrell Williams asked Vuitton’s in-house master perfumer Jacques Cavallier-Belletrud to capture the energy of sunshine. The result—named in reference to Williams’s home state, Virginia (which, they say, is for lovers)—is a bright, lively blend of galbanum, cedarwood, sandalwood and ginger. $535 for 100 ml

Perfumehead La La Love

Los Angeles, USA

Consider this an olfactory ode to the City of Angels creatives who work as hard as they play. Perfumer Constance Georges-Picot’s gourmand concoction smells like a cocktail you could easily have one

too many of, with boozy Cognac notes mixing it up with vanilla absolute, incense, sandalwood and musk. Around $645 for 50 ml

Memo Paris Cappadocia

Cappadocia, Turkey

Turkey is among the world’s foremost saffron producers, and the spice’s earthy, tea-like scent takes centre stage in this effort by nose Gaël Montero. He balanced it with sandalwood, benzoin, myrrh and jasmine to create a warming scent that’s perfect for the cooler months but still works all year. $460 for 75 ml

Krigler Lindauer Löwe 08

Lindau, Germany

Bavaria’s answer to Capri, Lindau is a colourful island-resort town on the eastern edge of Lake Constance. Perfumer Albert Krigler loved it here so much that he dedicated a scent to the destination in 1908. His great-grandson Ben recently re-released the juice—a combination of green tea, geranium, amber and cedarwood—just this June. Around $960 for 100 ml

ILLUSTRATIONS BY Peter Oumanski

You may also like.

24/10/2024

First Among Equals

Women are an emerging force in the watch-buying market, but their influence hasn’t been reflected at executive level—until now. The She-suite are coming.

In an era when fierce online conflicts against total strangers are normalised, where the posting of a cat meme on Instagram can spark World War III, it should come as no surprise that the modern horological battleground is equally heated—especially the moment conversations around gender enter the fray. Should women wear men’s watches? Why are brands bothering to make unisex timepieces? What’s the correct wrist-to-watch ration on a lady? Do women even like watches? At any given time, all these questions and more are bandied around social media and internet forums of varying degrees of sageness. Australian women may have secured suffrage over 100 years ago, but their right to adorn their wrists with anything they see fit is clearly not sacrosanct.

What’s not up for debate, however, is that an increasing number of women continue to enter the global space as enthusiasts, collectors and buyers, undeterred by the surrounding noise. Global market research firm Allied Market Research estimates that by 2027, the women’s watch segment will be worth around $39.6 billion. And according to the watch platform Chrono24, the proportion of women who bought luxury watches of at least 40 mm in diameter—around the starting size point for a typical men’s timepiece—grew from 21 percent to 35 percent between 2019 and 2023.

Granted, numbers of this magnitude have piqued the interest of most major brands. But behind the gleaming boutique facades and slick advertising campaigns there remains a dearth of women in senior leadership positions. CPIH, a group that represents the interests of the Swiss watch industry, reports that only 17 percent of the top horology jobs are held by women.

“At the top of the pyramid, in the C-suite, we’re very few,” confirms Coralie Charriol, chairman and CEO of Charriol, the Geneva-based watch company started by her father Philippe Charriol in 1983. “There’s long been women in the manufacturing, marketing and sales sides. They’re just not at the top.”

“Being the boss is freakin’ hard” she continues. “You’re the decision maker. And I’ve made the decision to model my watches off of myself in the sense that I am trying to design for an active woman, a woman who has multiple roles in her life… of course there are many, many different kinds of women. You can’t design for everyone, but you hope that what you’re creating and your message is going to reach many people as possible.”

It’s no secret that throughout watchmaking history, male executives made and marketed timepieces that largely mirrored themselves in taste, and perhaps, appearance. But, as the watch segment enters a period of unprecedented growth—a report this year by Business Research Insights puts the industry’s market size at just over $200 billion by 2031—there are green shoots of hope that a more progressive outlook will spread across executive leadership, brand partnerships and marketing efforts.

Take this year’s Watches & Wonders exhibition in Geneva, where one of the most talked-about novelties was Vacheron Constantin’s Égérie Pleats of Time concept watch. A collaboration with Yiqing Yin, a Paris-based female haute couturier and brand ambassador, the timepiece included a perfume-infused strap woven with mother-of-pearl shards. Alexandra Vogler, CMO of Vacheron Constantin, previously worked in the fragrance industry. “Merging culture and art and high watchmaking, this is very interesting,” she told Robb Report at the Swiss conference. “For me, these emotional dots I connected, I did so across three teams because I know when mixing creatives that’s how you get to birth new ideas.”

In Vogler’s roughly two years as CMO, she’s rebuilt the brand’s portfolio and announced a collaboration with the Metropolitan Museum of Art. The three-year agreement will support various educational initiatives and bespoke collaborations, including the creation of Vacheron Constantin timepieces inspired by artworks from The Met collection.

A few booths away stood Jaeger-LeCoultre’s CEO Catherine Rénier, who’d recently commissioned two-Michelin-star chef Himanshu Saini to create the Precision Atelier, a gastronomic experience that delves into the science of ingredients. Rénier, who since our chat has been tapped to be Van Cleef and Arpels’ new boss, remarked: “Watchmaking is a very niche, initiated world. So we open up this world to a larger audience through another field that will showcase similar values. And then of course, the artistic dimension is important because we do feel that more and more that the relationship to your timepiece is the same as a piece of art.”

By incorporating voices from the spheres of fashion, culinary and fragrance—different domains, sure, but with shared values like precision, beauty and expertise—more varied connections to watch brands are formed beyond customers strictly interested in horology, who historically have skewed male. “I believe that you cannot talk to women the same way you talk to men about watches,” insists Coralie Charriol. “They respond to different touchpoints.”

This formula has already begun producing dividends. In February, the six variations of the Chronomat collection from Victoria Beckham for Breitling debuted, complementing the British designer’s spring/summer 2024 collection. A month earlier at Paris Fashion Week, couturier Tamara Ralph dressed her models in a limited-edition Audemars Piguet Royal Oak Concept Flying Tourbillon. Quite a way for Ilaria Resta, the marque’s incoming CEO, to make a statement. (It’s worth noting, too, that Resta joins Ginny Wright, CEO of Audemars Piguet Americas, in the C-suite of the Swiss company)

While fashion and fragrance are proving to be useful conduits for attracting more diverse audiences, female collectors are also expressing interest in more intricate timepieces.

“We have the opportunity to be in touch with more and more women and we are listening to what they want,” Resta told online magazine Revolution Watch in March (though, for the record, she declined an interview with Robb Reportfor this story). “There is a demand for complicated watches for women. The complications for women don’t necessarily have to be the same as those for men. I’ll give you an example. The Starwheel is an amazing watch that is very much loved by women. But at the moment, it only comes in a 41 mm diameter case. It is very appealing to women as a poetic representation of time and as a design statement, so of course we need to look into this.”

Female collectors throughout history, according to Vacheron Constantin’s Alexandra Vogler, have been rich veins of inspiration; in the 19th century, 30 percent of the letters received by the manufacture came from women. “We’ve had specific requests from our female clients for a rotating bezel, winding mechanisms. We have evidence in our archives demonstrating that women’s requests pushed the boundaries of innovation.”

Indeed, the history books show that women played a pivotal role in the development of modern timekeeping; it’s believed the first wristwatch was made for England’s Queen Elizabeth I in the 16th century, while in 1810, Caroline Bonaparte, the Queen of Naples, commissioned Louis Breguet to create a piece especially for her.

Perhaps, internet trolls, women are the original watch bosses after all.

You may also like.

24/10/2024